Your employees spend a lot of time creating a product that boasts function and form. With so much time and attention paid to manufacturing, few things are more frustrating than to spot flaws, scratches, and damages on your product during the final inspection. If luck is on your side, you may be able to discount the damaged aluminum product or part to recoup some of the manufacturing costs.

However, far too often, these types of performance-ruining blemishes or scratches can prevent components from being sold at all. In fact, damaged products and scratches are a key factor in the development of manufacturing scrap and can have a dually-damaging effect on your bottom line:

While some damages are a cost of doing business, there are several ways you can reduce and/or prevent scratches on your aluminum and other metal parts. Let's take a closer look at a few key steps you can take to prevent scratches on your aluminum and metal parts.

Stabilize to Prevent Scratches on Aluminum Parts & Components

Shipping and transportation may be the cause of a lot of product damage, but you can prevent scratches on aluminum and other metal components by properly securing them throughout the washing and finishing process. During the finishing and washing process, loose parts are likely to rattle around and get damaged or cause damage, especially with processes like ultrasonic cavitation.

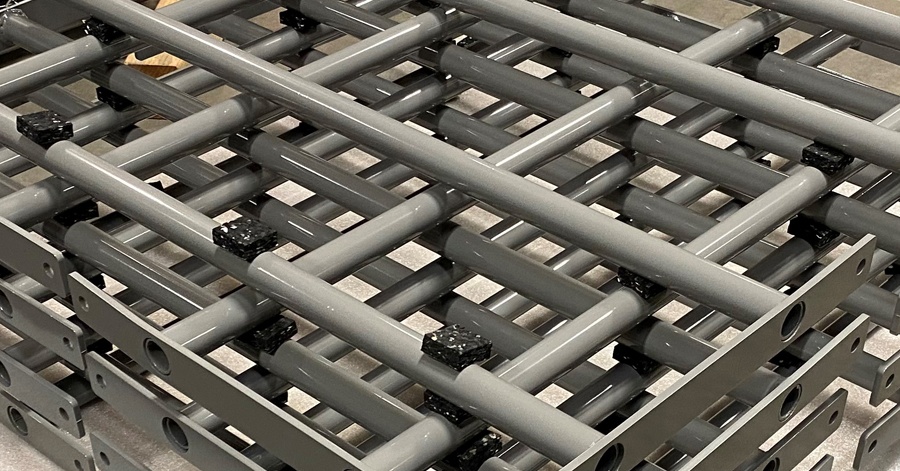

Instead of allowing the components or products to carelessly float around, it's vital to use solutions designed to protect the part and prevent scratches on aluminum and other types of metal. For example, you can use custom-formed baskets that are specifically designed to hold your parts through the washing and finishing process.

Another solution is to consider using baskets with dividers to achieve the same goal. If your component or part isn't suitable for baskets, look for dividers or separator pads that boast the ability to reduce rattling, which can help prevent the common part-to-part contact scratches.

Prevent Friction Scratching on Aluminum and Other Metals by Cleaning

Friction scratching can occur at various points throughout metal fabrication, especially when there is a formation with a built-up edge. The built-up edge commonly develops when working with metals like aluminum, stainless steel, or low carbon steel. In these scenarios, the plate gets damaged and causes friction scratches as it's dragged across the mold.

You can prevent friction scratching on aluminum and other metals by ensuring you regularly clean the worktable and the sheet metal you're working with. Make sure there is no debris, which can help prevent scratches to your metal components. Another way to reduce friction scratching is to reduce the punch speed to help further mitigate the likelihood of a built-up edge.

Reduce and Prevent Scratches with WOW Pads

Whether you handle powder coated products, raw aluminum products, or any other type of metal products that you do not want to be scratched, Frank Lowe's new WOW Pads are a value-add solution that can lead to significant savings. WOW Pads are engineered to provide the exceptional protection your product deserves.

These small and mighty pads are manufactured from either NeoRebond or White Polyfoam material that includes an easy-to-remove adhesive backing, which makes application as simple as peel-and-stick. WOW Pads are a proven, cost-effective way to protect aluminum, painted metals, powder-coated metal, and raw metal products throughout storage and even shipping. WOW Pads are the perfect solution for securely storing, shipping and separating products by:

Each WOW Pad can be custom die cut to the specific needs of your product to best prevent scratches on aluminum and other metals.

Contact Frank Lowe for WOW Pad Samples

At Frank Lowe, we're proud to offer the premier protective solution in WOW Pads. Since we've introduced these revolutionary separating and shipping solutions, we've helped several metal finishing companies and manufacturers save money by dramatically reducing product damage. However, you don't have to take our word for it! Read how our clients have used WOW Pads to protect their products and increase efficiencies.

And when you're ready to experience WOW Pads for yourself, don't hesitate to give us a call! Make sure to request your free WOW Pad sample.