Although Valentine’s Day is in February, we like to show our customers love 365 days a year with the sweetest kiss cut parts and components available. While other die cutting companies may be rigid, our kiss cutting solutions are as flexible as our full complement of non-metallic materials. Continue reading to learn a few reasons why Frank Lowe’s kiss cutting services are the sweetest.

Our Kiss Cutting Services Are a Cut above the Rest

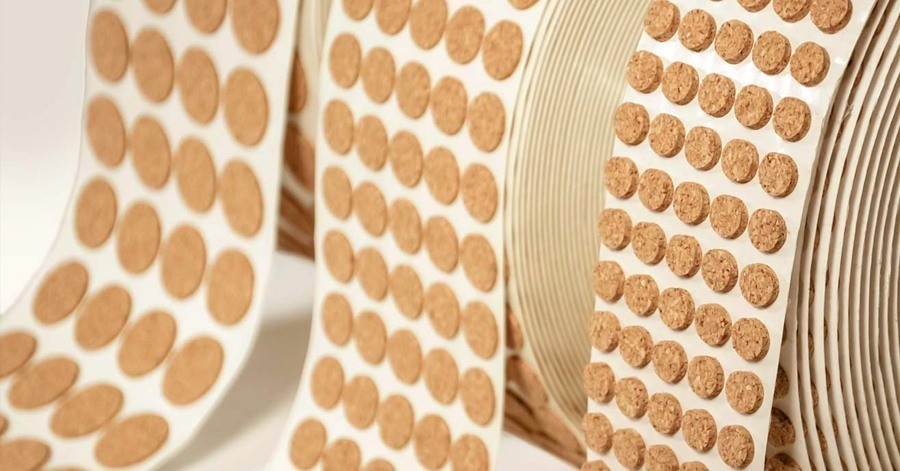

At Frank Lowe, we offer kiss cut products and components customized in the specific shape and size of your choosing. Kiss cutting explains when the elastomer or parts are fully cut through — without cutting the throw-away, adhesive lamination backing or paper liner. The process of kiss cutting got its name because the components are fully cut through, but the die gently "kisses" the backing paper without cutting through it.

Why Choose Kiss Cut Peel-and-Stick Parts on a Roll?

If you're looking to improve your manufacturing process, our kiss cut parts and components on a roll may be the ideal solution. We can create custom kiss cut products to your exact specifications and include a pressure-sensitive adhesive backing to create peel-and-stick components that make application as easy as possible. Whether you use an assembly line, hand application, or robotics, our kiss cut products can offer countless benefits.

Kiss Cut Components Are Easier to Handle

With kiss cut products, the backing paper is never cut. As a result, the kiss-cut components can be shipped and supplied in neat and tidy rolls. These rolls are much easier to handle. Kiss cuts on a roll also work to protect the product from deforming or damage during transit.

Kiss Cut Parts Offer Faster Assembly

If you’re assembling a product at your facility, the kiss cut parts can greatly improve productivity and facilitate faster assembly. You can easily set up a fixture for the roll at work stations and allow your workers to quickly remove parts from the roll and apply.

This beats attempting to remove backing from each individual component — possibly having to get their fingernail under each part. With parts kiss-cut on a roll, the assembler can simply continue to remove parts from the roll and apply with utmost efficiency.

Kiss Cutting Reduces the Cost of Production

With Frank Lowe’s kiss-cutting technology, you can improve the speed and efficiency of your assembly process. Kiss cut components reduces the need for assemblers to waste time digging through a bag or a box, separating parts stuck together by static or adhesives, and removing the liner. As a result, it can reduce your overall labor costs, which is directly related to reduced production costs.

Kiss Cut Components Are Flexible

Often, our kiss cut products are used to create peel-and-stick type of products equipped with pressure-sensitive adhesives. In either case, our kiss cut products can be applied manually by hand on your assembly line or with high-tech industrial robots or other types of automated equipment.

What Types of Kiss Cut Materials Are Available?

At Frank Lowe, we regularly perform kiss cutting with an expansive array of quality elastomers, including:

We offer the flexibility to kiss cut a wide array of other non-metallic pressure sensitive materials, such as

Simply put, the kiss cutting possibilities are endless when you partner with Frank Lowe.

Why Are Frank Lowe’s Kiss Cuts the Sweetest?

Based on more than 65 years of experience, we’ve learned that kiss cutting requires a bit of finesse and advanced equipment. At Frank Lowe, we offer both as well as the ability to support high-speed, high-volume kiss cutting using a plethora of cutting-edge methods. Whether you need a large or small order of kiss cut products, you’ll quickly find our kiss cutting is the sweetest.

Most importantly, we offer the industry expertise and technical knowledge to meet your needs and exceed your expectations with each cut. All of our kiss cut parts are based on your precise specifications and delivered on convenient rolls or sheets.

Contact Frank Lowe to Explore, Pursue, and Create Kiss Cuts

If your staff is assembling products in house, then you will greatly benefit from the sweetness of our kiss cuts. Most importantly, if you don’t know whether kiss cutting can help, we will help you explore, pursue, and create excellence.

We’re looking forward to discussing the sweet benefits of kiss cutting with you. Let’s talk! Contact Frank Lowe today to learn more about kiss cutting.